Biomass Recycling Facility in Kurobe City Sewage Treatment Plant

The first PFI project under the BTO scheme for sewage systems

We establish resource circulation facilities utilizing coffee grounds, which are suited not only for large cities but also for small- or middle-sized cities.

This case example is drawing attention as a pioneering approach utilizing the power of the private sector to tackle the issue of sludge treatment and disposal costs in sewage management. The project won the Ministry of Land, Infrastructure, Transport and Tourism Minister's Award 2011 "Recycling-based Sewage prize (Sustainability category)."

Strong private sector utilized as a powerful solution for providing efficient sewage services

New approach to sewage sludge treatment and reduction of treatment cost

Kurobe City has outsourced the task to dispose dewatered sludge, but at the same time, it has often been confronted with the situation where it is difficult to make long-term disposal plans due to the significant fluctuations of disposal costs. Also, a dedicated treatment facility operated by an inter-municipal association of the region was abolished, thereby a further cost increase has been expected as a result of the increased amount of waste received by the city's sewage treatment plant.

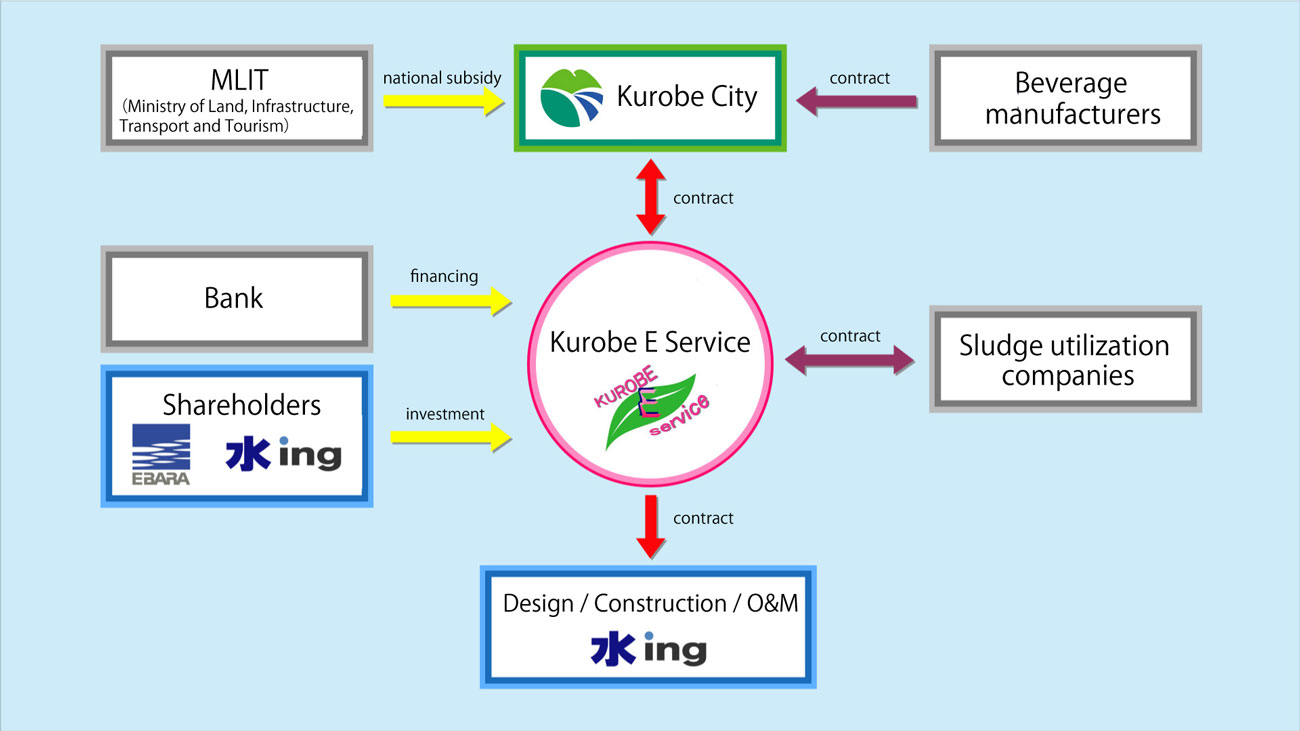

The Project for Introduction and Operation of Biomass Recycling Facility in Kurobe City Sewage Treatment Plant, the first PFI project targeting a sewage plant in Japan, is managed under the Build-Transfer-Operate (BTO) scheme, where a special purpose company named "Kurobe E Service," represented by the Swing Corporation, takes charge of fund procurement, along with design, construction, maintenance and operation.

Advantages to Kurobe City are:

- Improvement of operational efficiency achieved through the smooth management of a project adapted to fresh technologies

- Availability of state-of-the-art biomass utilization technologies, acquisition of sales destinations of byproducts, and reduction of treatment cost

- Leveling of costs by consigning overall operations of the project including design, construction, maintenance, and management

【Project schematic diagram】

Project Name

Construction and Operation of Biomass Recycling Facility in Kurobe City Sewage Treatment Plant

Project Structure

PFI(BTO)

Project Period

Design/Construction Period: April, 2009 to April, 2011

Management/Operation Period: May, 2011 to April, 2026 (for 15 years)

Waste Types

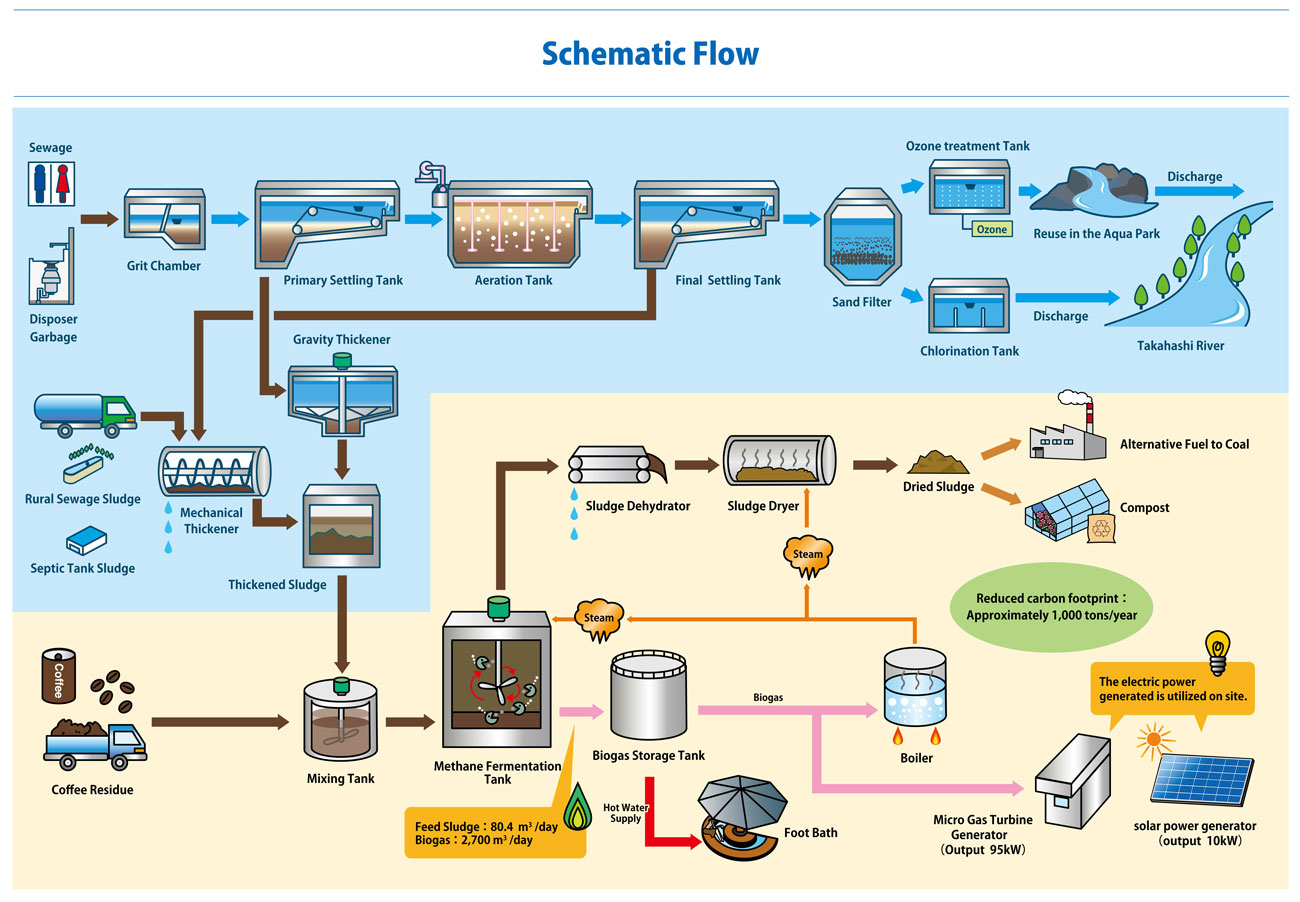

Sewage sludge, Rural sewage sludge, Septic tank sludge, Disposer waste (from existing Waste Water Treatment Plant )

Industrial food wastes (from beverage manufacturers)

Total Project expense

Approx. 3.6 billion yen

SPC

Kurobe E Service Co., Ltd.

Shareholders: Swing Corporation, Ebara Corporation

Shift from a treatment plant to a resource circulation facility

Coffee grounds are the key

Sludge drying facilities, which previously required the use of fossil fuels, have now achieved stable operation ensuring an energy-independent system with no fossil fuels, by taking advantage of the high calorific levels in coffee grounds.

Coffee grounds are mainly provided by beverage manufacturers in the prefecture.

Sludge recycling

Sewage sludge is mixed with coffee grounds, and then processed by methane fermentation, dewatering and drying. The resulting dry material becomes reduced in volume, by half or less than what was conventionally processed by the outsourcing prior to introducing the new system, and is effectively used as resources such as compost and fuel.

Quantity of biomass received: 29,132 m3/year (Planned value in FY 2014)

Sewage Sludge

24,346m3/year

Rural Sewage Sludge

1,080m3/year

Septic Tank Sludge

134m3/year

Disposer Waste

688m3/year

Coffee Grounds

2,884m<sup>3</sup>/year

Specifications of main equipment (Scale of facility)

Methane Fermentation Tank

80.4m3/day

Biogas Storage Tank

600m3

Biogas

2,700m3/day

Micro Gas Turbine Generator

Output Power: 95kW

Solar Power Generator

Output Power: 10kW

Sludge Drying Facility

The 3rd Floor, and Basement Floor

Eco-friendly facility packed with technology and new ideas

The facility generates one million cubic meters of biogas per year, which is equivalent to 0.6 million liters of kerosene. Swing Corporation possesses sufficient knowledge and experience to maximize the effectiveness of the energy.

Energy independence

This energy-independent facility is designed to use biogas as the thermal source for heating the steam dryer for dewatered sludge and the methane fermentation tank, without relying on fossil fuels.

Left:Biogas Storage Tank ,Right:Methane Fermentation Tank

More than 50% reduction in electricicty costs

Our low-noise, highly maintainable micro gas turbine generator (max. output 95 kW) is used for biogas power generation, producing 380,000 kW per year on average. The electricity generated from biogas covers more than 50% of the total power consumption of the facility, and is also transmitted to the sewage treatment plant on the site during the downtime of the sludge dryer.

Micro Gas Turbine Generator

Installation of foot bath

Under our concept of "sewage service open to the public," we have installed a foot bath on the site to serve as an amenity to local residents so that they can feel more familiar with biomass energy.

The water heated by biogas is pumped up from Kurobe's groundwater, one of the Selected 100 Exquisite and Well-Conserved Waters designated by Japan's Ministry of the Environment. Given the name "Bio-Yu (Bio bath)" by the public, this recreation spot enjoys great popularity.

Foot Bath

Effective use of dry material

Some of the dry material produced through the treatment process at the facility is sold as high-quality fertilizers or fuel for power generation boilers.

For cultivating beautiful flowers

The dry material is registered as a fertilizer named "Kurobe Ryokkaoh (Kurobe greenery and flower king)" and sold to flower farms.

In Himi Aiyama Garden, you can see picturesque scenery of blooming flowers grown with the fertilizer.

HIMI AIYAMA Garden

For utilizing as fuel for power generation boilers

The dry sludge can be also used as a fuel to generate power for boilers. We sell the dry sludge to companies in Toyama which support our intention to promote local production and consumption of energy.

The fuel, positioned as an alternative to fossil fuels, is contributing to CO2 reduction.

Promoting local production and consumption of energy through innovative efforts

The biomass energy project utilizing sewage sludge, for which proposals were solicited from the private sector, allows for various innovative approaches in regard to independent procurement of coffee grounds, as well as service fees. We are running the project with a focus on the collection of coffee grounds and sales of dry material, in order to ensure the stable operation of the facility.

While seeking a closer cooperation with Kurobe City, we will strive not only for reliable facility operation but also for the promotion of local production and consumption of energy, through the contract period of 15 years for this model project.