Hitachi Cement Co., Ltd., Kandatsu Resource Recycling Center Biomass Plant

Japan's largest methane fermentation facility in compliance with the Food Recycling Law

Significantly contributing to the prevention of global warming and the creation of a recycling-based society

The city of Tsuchiura located in southern Ibaraki Prefecture is famous for hosting National Fireworks Competition, Kasumigaura lake in the east and Mt. Tsukuba in the west.

Tsuchiura City, which has a history and tradition of abundant water and greenery, formulated a biomass town plan in 2010.

A study committee consisting of industry, government, academia, and citizens, including Hitachi Cement Co., Ltd., was established, and a biomass utilization scheme was put together. The Kandatsu Resource Recycling Center Bio-Plant was positioned as the core facility of this initiative.

Japan's largest methane fermentation facility

Capacity

food waste

135.9t/day

Main facilities

Pre-treatment

6 lines (business/household kitchen waste, processed food waste (solid/liquid), production residue, etc.)

Methane fermentation tank

1,800m3/tank × 2

Composting tank

66m3/unit × 2

Conform to the Food Recycling Law

The facility complies with the Food Recycling Law, which recycles food waste into "biogas" by methane fermentation treatment and "organic compost" by composting fermentation treatment.

Japan's first hybrid waste treatment facility with an incineration facility

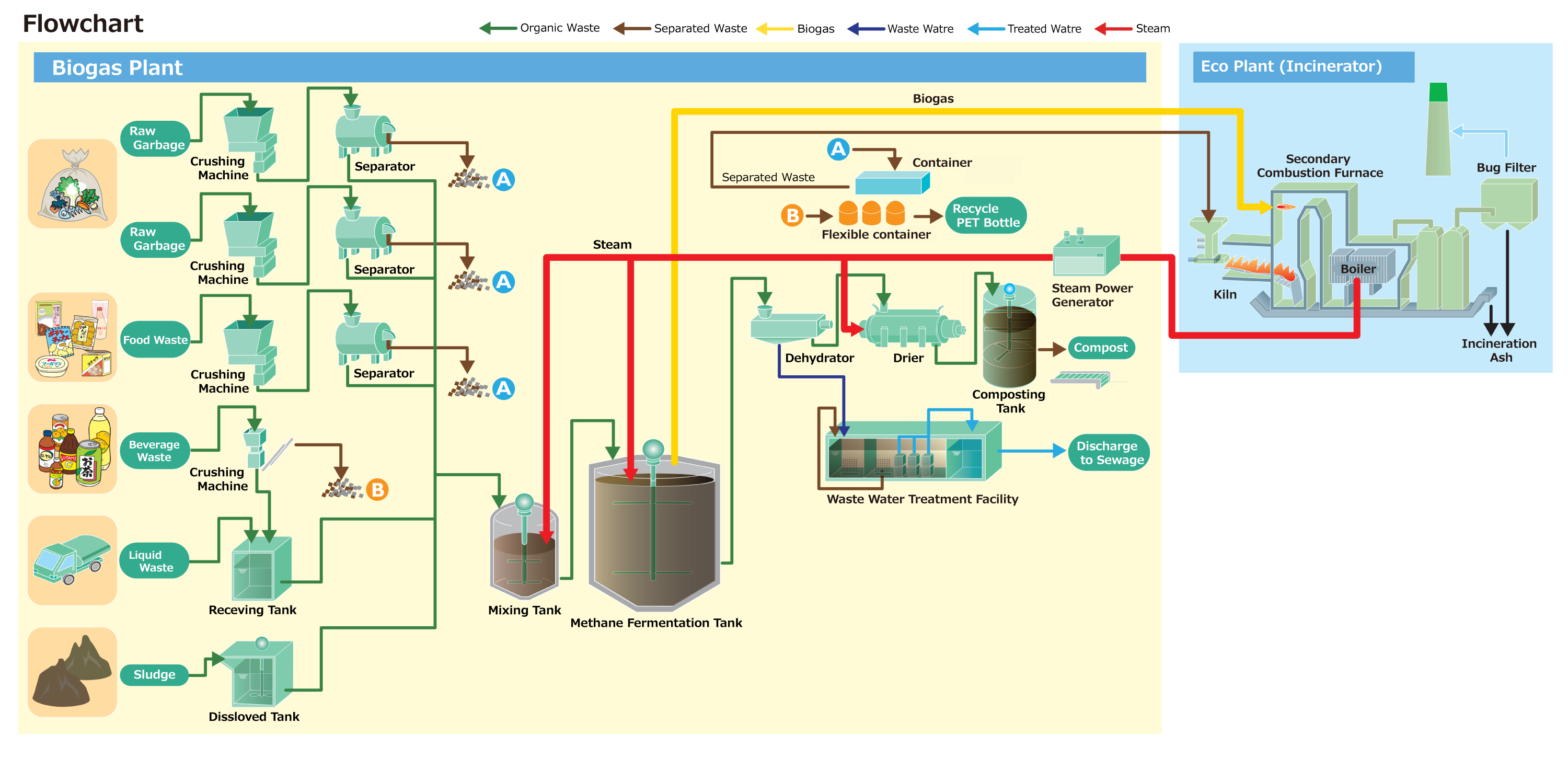

By installing a methane fermentation treatment facility called the Bio-Plant at the Eco-Plant, an existing incineration facility, we can select and feed waste suitable for each facility, and achieved hybrid waste treatment system in cooperation with each other.

Biogas

Bio-plant ⇒ Eco-plant: Used as alternative fuel for auxiliary fuel (heavy oil) (equivalent to 5.5 kl/day)

Odor

Bio-plant ⇒ Eco-plant: Used as combustion air (Odor is treated)

Containers and packaging

Bio-plants ⇒ Eco-plants: Incinerated

Surplus steam

Eco-plant ⇒ Bio-plant: Used as a heat source after decompressed power generation by a steam generator (from 1.4MPa to 0.4MPa, about 100 kW).

Thorough countermeasure for odor

In order to prevent odor leakage to the outside of the building, dumping to the hopper by the carrying-in vehicle is possible only when the building shutter is completely closed, and a system to spray deodorant automatically is installed.

In addition, each facility is sealed and kept under negative pressure by odor fans, and drawn odor is treated with odor control equipment.

We use three types of odor control method: combustion (eco-plant), chemical scrubbing, and activated carbon adsorption, and are thoroughly implementing environmental measures for the residents living in the vicinity.

Left: chemical scrubbing tower

Right: activated carbon adsorption tower

Shinji Ueda

Biomass Technology Unit, Biomass Technology Dept, Resource Recovery Technology Division

Since the biomass used as the raw material varies from customer to customer, the optimal equipment and process will vary from one facility to the next.

We believe that it is important to build facilities with our customers by repeatedly studying, discussing, and proposing with fully understanding the needs and local characteristics of our customers.

At the Bio Plant of the Kandatsu Resources Recycling Center, to accept food waste in a wide variety of forms (packing type, properties, and delivered vehicles), and to establish the optimal mutual cooperation with eco-plants were major needs for our customers.

I believe our past achievements along with the six different types of pretreatment facilities and hybrid collaborative proposals were highly evaluated by our customer.

The technology and experience of various mixed methane fermentation processes, such as livestock waste, wastes from beverage plants, and sludge, are also utilized here at the Kandatsu Resource Recycling Center Bio-Plant.