Deni Light System

Swing Engineering, with a half-century track record of supporting night soil treatment systems, introduces a new night soil treatment technology.

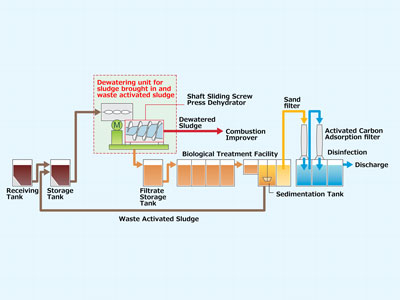

A new night soil treatment technology,“Deni Light System” adopts direct sludge dewatering, followed by biological denitrification process and tertiary treatment processes

Deni Light System is a comprehensive treatment system combining direct sludge dewatering as the pretreatment, followed by biological denitrification process and tertiary treatment processes based on the “Swing Engineering’s denitrification treatment process = Denipack Process” technology, which is a core technology Swing Engineering developed for night soil treatment.

The most striking feature of the system is its effectiveness to attain a result similar to a membrane filtration system, while adopting a simple process without complicated pretreatment or membrane separation equipment. Further, the dewatered sludge produced through Swing Engineering’s Value Sludge System achieving direct sludge dewatering can be a sludge combustion improver (with 70% or less moisture content).

“P Deni Light System”, capable of recovering phosphorus, is also available.

Schematic Flow

Three kinds of “lightness” assure continuous stability in operational services

The direct sludge dewatering process dewaters septic tank sludge and/or human waste brought in by tankers together with waste activated sludge generated from the same premise. The process contributes to reducing pollutant load to the following biological denitrification process. This system also contributes to equalizing characteristics of feed pollutant to the following biological denitrification process. This process design achieves downsizing and reductions in number of equipment and water tanks to be installed, achieving three kinds of “lightness”.

Lighter CAPEX and OPEX!

Examples of comparison with our existing systems are as follows.

■Construction cost: Reduced by 15%

■Maintenance cost: Reduced by 20%

■Power usage cost: Reduced by 30%

Lighter operational burden!

Adopting the direct sludge dewatering process prior to the biological denitrification processes reduces pollutant load on the biological denitrification process and minimizes the feed fluctuations, achieving stable system operation. Water quality of treated water through Deni Light System is equivalent to that of a membrane filtration system.

Lighter environmental load on earth!

Efficient and compact-sized system reduces CO2 emissions and achieves facilities friendly to the environment.

■Reduced power consumption

Reducing the number of devices to be installed and downsizing them help to cut electric power consumption.

■Savings in transportation fuel

Achieving moisture content at under 70% reduces the volume of dewatered sludge, saving fuel used to transport the sludge outside of the plant.

■Reuse of sludge as combustion improver

Dewatered sludge is usable as a combustion improver, allowing savings on fossil fuels consumed at waste incineration facilities or similar.